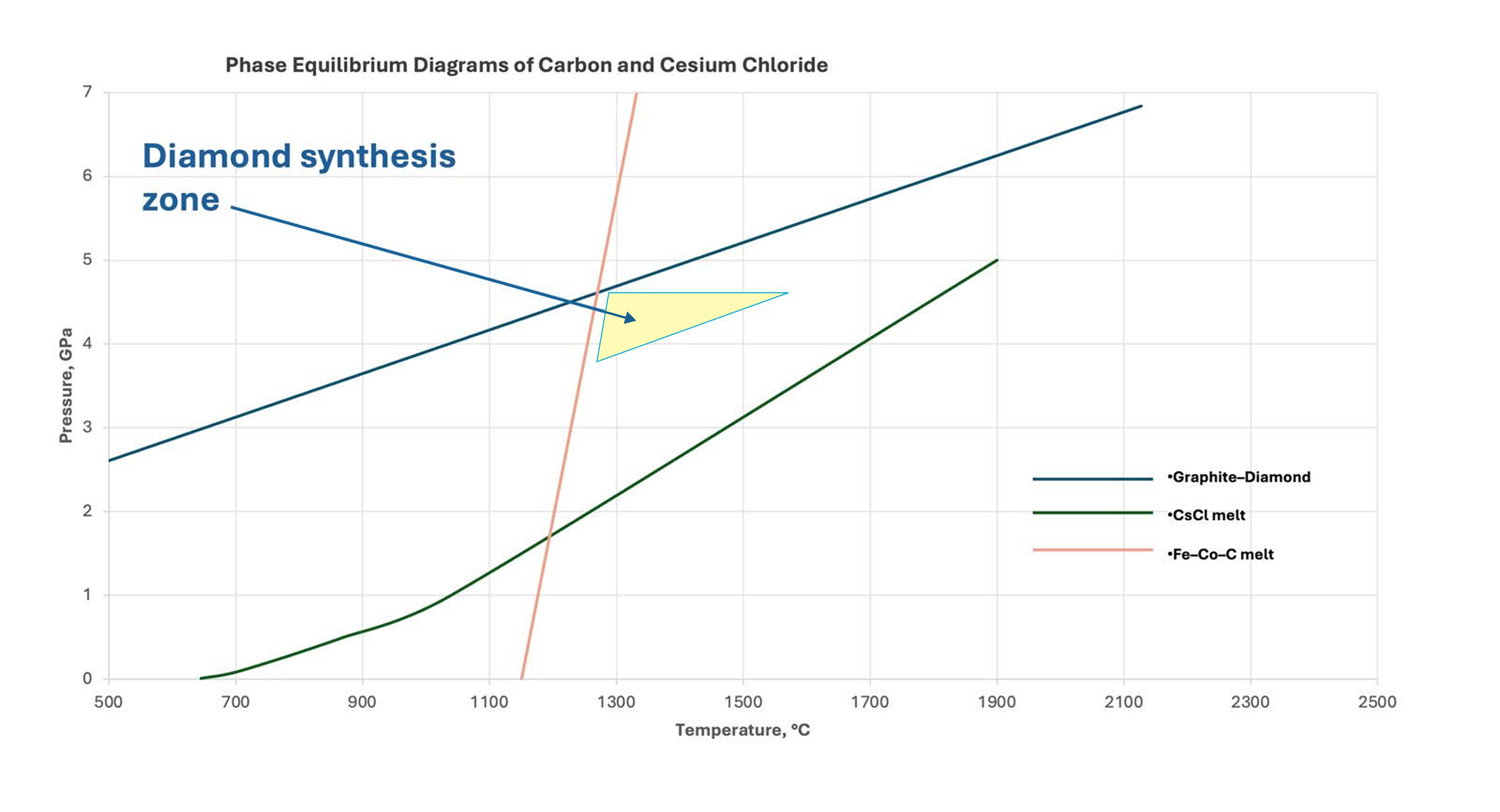

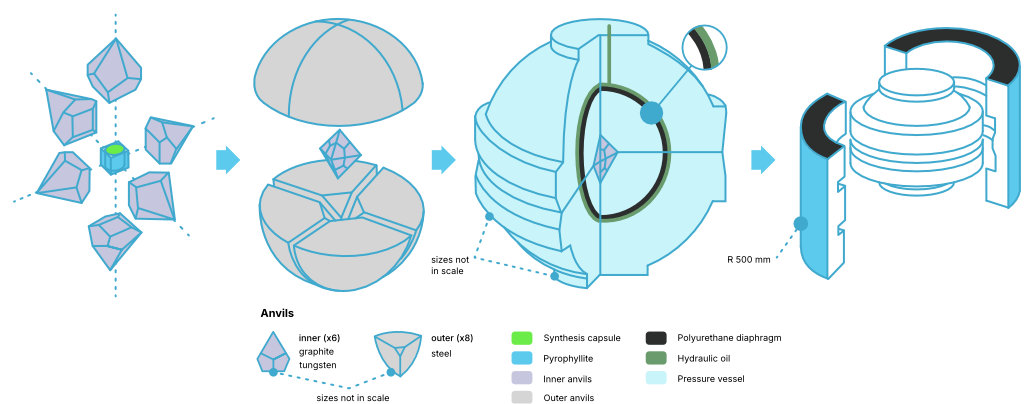

At EcoDiamond, we specialize exclusively in High Pressure High Temperature (HPHT) diamond growth technology - an approach that replicates the natural formation conditions of diamonds deep within the Earth’s mantle. Unlike chemical vapor deposition (CVD), which currently dominates much of the jewelry market due to its relative affordability and high-volume production, HPHT growth allows us to create diamonds with exceptional crystallinity, purity, and structural perfection.

Interestingly, even in CVD growth, the process begins with a substrate - typically a diamond seed plate—onto which carbon atoms are deposited. These seed plates are often produced using HPHT technology, especially when precision is required. At EcoDiamond, we develop tailor-made seed crystals not only for jewelry-grade diamonds with optimized size and clarity, but also for high-tech applications requiring specific properties from the very beginning - properties that we embed directly into the crystal’s structure during its growth.